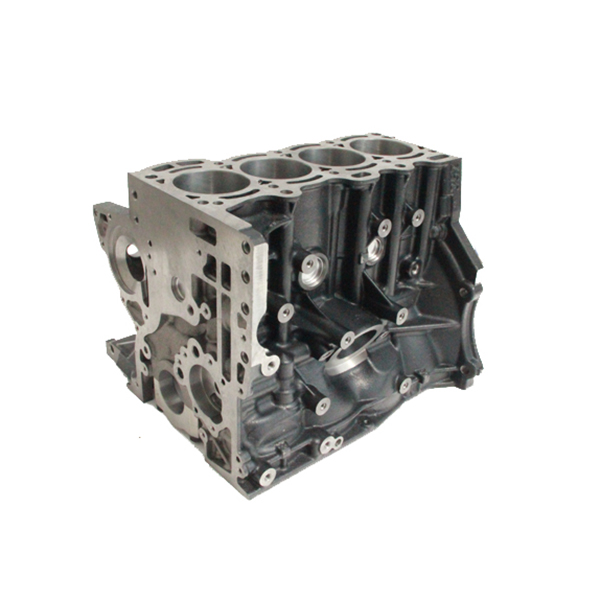

OEM Best Die Casting Cylinder Block Assembly Manufacturers – Engine Cylinder Block CE12 – Zhengheng

OEM Best Die Casting Cylinder Block Assembly Manufacturers – Engine Cylinder Block CE12 – Zhengheng Detail:

Engine cylinder sand molding material

Sand casting

Furan resin

Casting sulfonic acid curing agent

Furan film removal agent

Silane

Sand mold coating

Molten iron for engine block casting

Pig iron

Scrap

Ferrosilicon

Ferromanganese

Pyrite

Electrolytic copper

Silicon carbide

Ferrochrome

Tin

Recarburizer

Inoculant

Engine block after casting process material

Steel shot

Ceramic grinding wheel

Product material: HT250

Product weight: 31.83KG

Product size: 380*400*270.5

Product material: EN-GJL250

Product displacement: 1.2L

Cylinder diameter * stroke (mm) : 75.4*115

The CE12 three-cylinder cast iron engine block produced by Positive Constant Power is used for extended-range electric vehicles. The main principle of extended-range electric vehicles is that a small displacement engine drives a generator to charge/generate electricity for the battery pack, and then the battery pack drives a driving motor to drive the model. This is the core element of extended-range electric vehicles. The advantage of extended-range electric vehicles is that they are equipped with internal combustion engines, but they can achieve power data and fuel consumption levels that cannot be achieved by engines with similar displacement.

The cylinder block is one of the most important parts in the automobile engine and even in the automobile. The machining quality of the engine directly affects the quality of the engine, and then affects the overall quality of the automobile. Therefore, the manufacturing and processing of the engine cylinder block has long been paid attention to by the automobile production enterprises. Engine cylinder block is the basic parts and skeleton of the engine, and also the basic parts of the engine assembly. The function of cylinder block is to support and ensure the accurate position of piston, connecting rod, crankshaft and other moving parts when they work, and ensure the ventilation, cooling and lubrication of the engine. Car engine cylinder block and crankcase often cast into one, called the cylinder block – crankcase. Because the cylinder block usually works in high temperature, high load, severe wear conditions, under the greater pressure, the force is complex. At the same time work under the immersion of gasoline, the working environment is humid.

The use of performance requirements of the cylinder: the working conditions of the cylinder determines that the cylinder must have high strength, high stiffness, high hardness, high wear resistance and good heat dissipation, at the same time to have a good sealing, leakage resistance, vibration reduction and so on.

The materials used in engine cylinder block are generally gray cast iron, cast aluminum or cast steel. The use of gray cast iron can meet the requirements of high strength, high stiffness and high wear resistance, and the process performance, shock absorption, excellent machinability, and low cost.

We are a professional engine cylinder block manufacturer from China, has accumulated more than 20 million cylinder blocks, wholesale quality products, according to the engine cylinder block drawing co-research and development and manufacturing, we have professional technical team support and perfect after-sales service. Look forward to working with you!

1. We focus on engine block casting and engine block production for more than 40 years, with many years of industry experience and a strong database of cylinder blocks.

2. We have successfully cooperated with many enterprises around the world, and have professional sales personnel in various languages.

3. Focus on OEM customization, you can get good quality and the most competitive price from us.

4. Passed the international advanced IATF 16949 system certification, standardized production.

5. Coordinated development, from casting to machining to provide strong technical support, customer new product development success rate reached 100%.

6. At the same time, we have a casting factory and a machine processing factory, providing one-stop finished products from mold, casting and processing.

Packing details:

1. Original packaging: 1PC/piece, 8 boxes/piece (the quantity depends on the product); Plastic packing + export laminate box

2. Special packaging: can be customized, warmly welcome to contact us for more details.

Transportation:

1. Standard export packaging, strong packaging to ensure long shipping and international express.

We have professional staff to prepare the goods, pack and pack to ensure punctual delivery and strong packing.

3. Customers can choose their own ship agency or our long-term cooperation ship agency.

1. Cylinder block spot: If there is inventory, generally 15-20 days after receiving the payment can be delivered.

2.OEM products: delivery will be arranged within 30-65 days after receipt of formal drawings. (Depending on the specific product)

1. Accept OEM manufacturing

2. Deliver the goods to our customers quickly and accurately.

3. Professional technical team and strict quality control system, to ensure that the best parts to your hands.

4. One-stop procurement of engine cylinder block components to help you reduce the cost of parts procurement.

1. Q: Can I add my logo on the product?

Yes, welcome custom logo, OEM production.

2. Q: Can you use our drawings to develop parts?

Yes, please provide drawings with technical requirements to protect intellectual property rights.

3. Q: Do I need to pay the mold fee again next time I order?

A: It is not used within the mold life. After the mold life expires, it can be negotiated according to the demand.

4. Q: What are your payment terms?

A: T/T 50% deposit, 50% before shipment. We will send you pictures of the fully packed goods before shipment

5. Q: How do you make our business a long-term good relationship?

Answer: 1. We maintain good quality and competitive prices to ensure that our customers benefit;

2. We respect every customer and regard them as our friends. We sincerely do business with them and make friends no matter where they come from.

Product detail pictures:

Related Product Guide:

We stick with the theory of "quality first, company first, steady improvement and innovation to satisfy the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for OEM Best Die Casting Cylinder Block Assembly Manufacturers – Engine Cylinder Block CE12 – Zhengheng , The product will supply to all over the world, such as: Mombasa, Iran, Dominica, Selling our products and solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.