China Wholesale Bearing Cap Factory Factory – Cast aluminum engine sprocket cover – Zhengheng

China Wholesale Bearing Cap Factory Factory – Cast aluminum engine sprocket cover – Zhengheng Detail:

Product material: ADC12

Product weight: 1.7kg

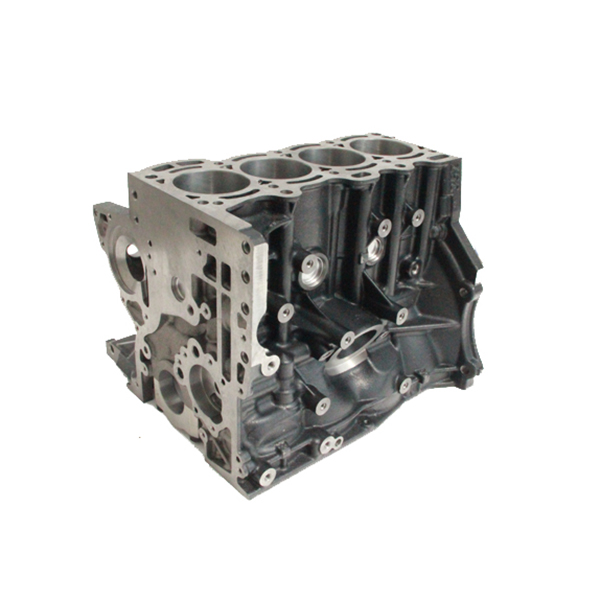

The sprocket cover produced by Zhengheng Power is fitted with 4A13 engine block for light trucks, minivans and vans. The engine sprocket chamber cover plate comprises a cover plate body, the upper surface of the cover plate body is provided with a convex hull, and the lower surface of the cover plate body is concave towards the convex hull to form an accommodating cavity; The accommodating cavity is provided with a diamond flange for mounting the camshaft sensor, the middle of the diamond flange is provided with a mounting hole, the mounting hole is extended through the convex hull surface, both ends of the length direction of the diamond flange are respectively provided with a first threaded hole; The front side of the cover body is provided with a second thread horizontally arranged, and the circumferential edge of the cover body is provided with a plurality of connecting holes for the installation screw through; The lower surface of the cover plate body is provided with a plurality of support columns of different heights, which is convenient for processing, has a plurality of installation positions, and is lightweight.

Zhengheng power is a professional aluminum casting parts manufacturer from China, wholesale quality products, according to the engine cylinder block drawing co-research and development and manufacturing, we have professional technical team support and perfect after-sales service. Look forward to working with you!

Process Design -> Mould -> Die Casting -> Deburring -> Rough Inspection -> Processing -> Finished Product Packaging

1. Zhengheng Power focuses on engine block casting, cast aluminum engine block production, has rich industry experience and a strong cylinder database.

2. Have professional sales staff in various languages, and cooperate with many well-known enterprises in the world.

3. Focus on OEM customization, you can get good quality and the most competitive price from us.

4. Passed the international advanced IATF 16949 system certification, standardized production.

5. Coordinated development, from casting to machining to provide strong technical support, customer new product development success rate reached 100%.

6. At the same time, we have a casting factory and a machine processing factory, providing one-stop finished products from mold, casting and processing.

7. Have from 200 to 6000 tons of die casting machine, can produce a variety of aluminum parts.

Packing details:

1. Original packaging: 1PC/piece, 8 boxes/piece (the quantity depends on the product); Plastic packing + export laminate box

2. Special packaging: can be customized, warmly welcome to contact us for more details.

Transportation:

1. Standard export packaging, strong packaging to ensure long shipping and international express.

2. We have professional staff to prepare the goods, pack and pack to ensure punctual delivery and strong packing.

3. Customers can choose their own ship agency or our long-term cooperation ship agency.

1. Sprocket cover spot: if there is inventory, generally 5-10 days after receipt of payment can be delivered.

2.OEM products: shipment will be arranged within 40-60 days after receipt of formal drawings. (Depending on the specific product)

1. Accept OEM manufacturing

2. Deliver the goods to our customers quickly and accurately.

3. Professional technical team and strict quality control system, to ensure that the best parts to your hands.

4. One-stop procurement of engine cylinder block components to help you reduce the cost of parts procurement.

1. Q: What aluminum castings can you produce?

Answer: we have 200~6000 tons of die castings, we can undertake all kinds of aluminum business.

2. Q: What process do you use to produce aluminum castings?

Answer: we have low pressure, high pressure, gravity production line, according to product characteristics and requirements to develop the production process.

3. Q: Can you use our drawings to develop parts?

Yes, please provide drawings with technical requirements to protect intellectual property rights.

3. Q: Do I need to pay the mold fee again next time I order?

A: It is not used within the mold life. After the mold life expires, it can be negotiated according to the demand.

4. Q: What are your payment terms?

A: T/T 50% deposit, 50% before shipment. We will send you pictures of the fully packed goods before shipment

5. Q: How do you make our business a long-term good relationship?

Answer: 1. We maintain good quality and competitive prices to ensure that our customers benefit;

2. We respect every customer and regard them as our friends. We sincerely do business with them and make friends no matter where they come from.

Product detail pictures:

Related Product Guide:

We constantly think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body along with the living for China Wholesale Bearing Cap Factory Factory – Cast aluminum engine sprocket cover – Zhengheng , The product will supply to all over the world, such as: Bogota, Germany, Peru, Now we have a dedicated and aggressive sales team, and many branches, catering to our main customers. We have been looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!